On December 22, 2021, on the first anniversary of the establishment of the Peking University Institute for Global Health and Development (PKU-iGHD), the “2021 Peking University Global Health and Development Forum: Human Health and Medical Innovation in the Era of Low Carbon Economy”was successfully held. Mr. Kasim Kutay, Chief Executive Officer, Novo Holdings delivered a keynote speech at Health Development in the Post-Pandemic Era Session.

In my view, the green transition will not happen at the pace or the cost desired if we do not harness the power of biotechnology. As everybody in the audience knows, we are in a golden era of biotech innovation. What we've seen over the last six or seven years in terms of biotech innovation is nothing short of staggering. I can give many examples, but perhaps the best one of late are the innovations associated with the application of mRNA and the successful use of that technology for vaccines against COVID. Ten years ago, mRNA was nothing but a moonshot, but today it is a reality. And I can give numerous other examples of how much progress and how many drug approvals and new healthcare developments have taken place of late. So we understand the impact of this biotech innovation on human health. What is less understood is the impact of this incredible innovation on industrial solutions.

I believe that the world needs a bioindustrial future. Bioindustrials will help us to act on climate change by reducing waste, increasing the use of sustainable materials and feeding growing populations. At the same time, from a company perspective, they can help you to win customers as consumers focus on sustainability, and they help firms meet new and growing sustainability regulations.

I came across this recent example of the power of bioindustrials. I will just use it to illustrate the growth in new applications of bioindustrial technology. Every year in India, farmers torch millions of acres, in order to prepare the fields for next year's harvest and crop. But today there is an alternative; rather than doing all this burning, there is a new spray in development using an enzyme which breaks down stalk stubble into fertilizer, with benefits to the soil and atmosphere.

Just gave you an example from agriculture, let me give you a few other examples of how bioindustrials are working today. On the left, I'm using an example of biobased fibers for things like apparel. So a very good example of that is German-based AM Silka manufacturer of recombinant silk; bacteria that produce silk which is one of the most durable, natural materials as many of you will know. And that silk can be used not only in apparel, but the company is, among other things, in discussions with certain airplane manufacturers like Airbus to explore the use of silk in airplane wings. Another example is a bag that a company called MycoWorks is developing with Hermes, the French luxury, good manufacturer. But it's not made from leather although it looks and feels like leather. It is made from mycelium fungus. There's no killing of animals. There's no need for cattle or whatever it is that you derive your leather from, and, therefore, less agricultural land being used, less carbon footprint, less methane, etc. And on the right, and this is an incredible innovation is building materials made with bacterial processing. There's a company called Biomason, based in the US that today uses bacteria to essentially produce bricks. It's the same microorganisms that are used in the production of coral reefs, and applied industrially, the results are bricks that are highly durable. And of course as we all know, building materials for example, such as cement are one of the biggest contributors to carbon pollution.

Now just to put things into perspective, I think, and believe we can do a lot more. But even if we did a little bit, just a little bit, the numbers are quite staggering. So what, if for example, 10% of the world's annual proteins were replaced with alternative protein. We would have 700 million tons of CO2 avoided, and 900,000 million kilometer squared of agricultural land saved. That's about equivalent to 50% of the EU's agricultural area. What if detergents were biobased? The use of enzymes in detergents has been around for decades and is highly successful. But unfortunately, a lot of detergents just don't use enough enzymes and still use chemicals.

If detergents were all biobased, five million tons of fossil based chemicals would be avoided. Another way of looking at it would be preventing 10 tons of chemicals from being poured down the drain every minute. It's absolutely staggering numbers. We're all familiar with biofuels, we're all familiar with the use of micro-organisms to turn starch into biofuel. And if 3% of all liquid transport fuels were biobased, 300 million tons of CO2 would be avoided. That's equivalent to 125 million cars off the road. . I use these examples because none of these are farfetched or require change that cannot be executed on over the course of the next decade.

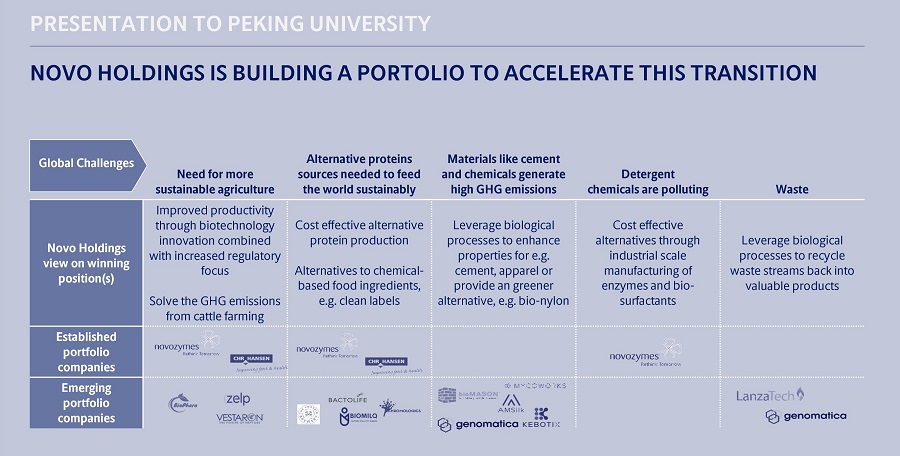

So in light of that, Novo Holdings is building a portfolio to accelerate this transition. We do this because we've been involved in bioindustrials for many years now; for decades since our founding. And that is because of our shareholding in Novozymes, which is a world leader in the production of enzymatic bioindustrial solutions. And given this knowledge and network that we have from Novozymes and later on from our shareholding in Christian Hansen, we are now expanding into other areas and have invested in all the companies that you see Figure 2.5 If we look at the need for more sustainable agriculture, we have companies like Vestaron which use a biopesticide. So that is an enzymatic based pesticide that helps avoid chemical pesticide. We have companies that supply alternative proteins to feed the world sustainably.

Finally waste, where today we can take industrial off-take gases like carbon , and convert those and recycle them. A very good example is a company called LanzaTech, which uses bacteria to take industrial off-take gas to produce jet fuel. And some planes have already been powered using LanzaTech's jet fuel in combination, of course, with fossil fuels as well.

There is are issues facing the greater adoption of bioindustrials. One is the scaling challenge as I call it, which is that a lot of these small companies find it very difficult to scale production to a level where that production becomes cheap enough, that it is competitive with the fossil fuel alternatives. That is a huge challenge.. So if you look at the big companies like Novozymes or Christian Hansen, then the economics of biosolutions become viable. But the scaling is very challenging initially.

It is also challenging for those companies to scale in a manner that maintains the stability of the quality of the microorganisms that they're trying to produce. e We will gradually work and develop and overcome those challenges with time. But it is a serious one. The other big challenge is the regulatory pathways. And whether we're talking about Europe or China, the US and other jurisdictions, there are regulatory pathways that frankly have not kept up with the developments on the biotechnology side. And those pathways are still, in many instances, archaic and arcane and do not allow the approval of bioindustrial solutions to take place at the speed we need.. Very often there are multiple agencies that need to be involved in a regulatory approval for anything relating to genetic research or GMO or call it what you will. And I will give you an example in Europe where bioindustrial products very often can take up to seven to eight years to receive approval, versus in the US for example, where we're talking about two to three years. So a lot of regulatory hurdles to overcome on a global basis, but I would urge all policy makers, all those that are focused on hastening the green transition to focus on simplifying and speeding regulatory pathways in order to realize the goalof having bioindustrials play a more important role in decarbonizing our planet.